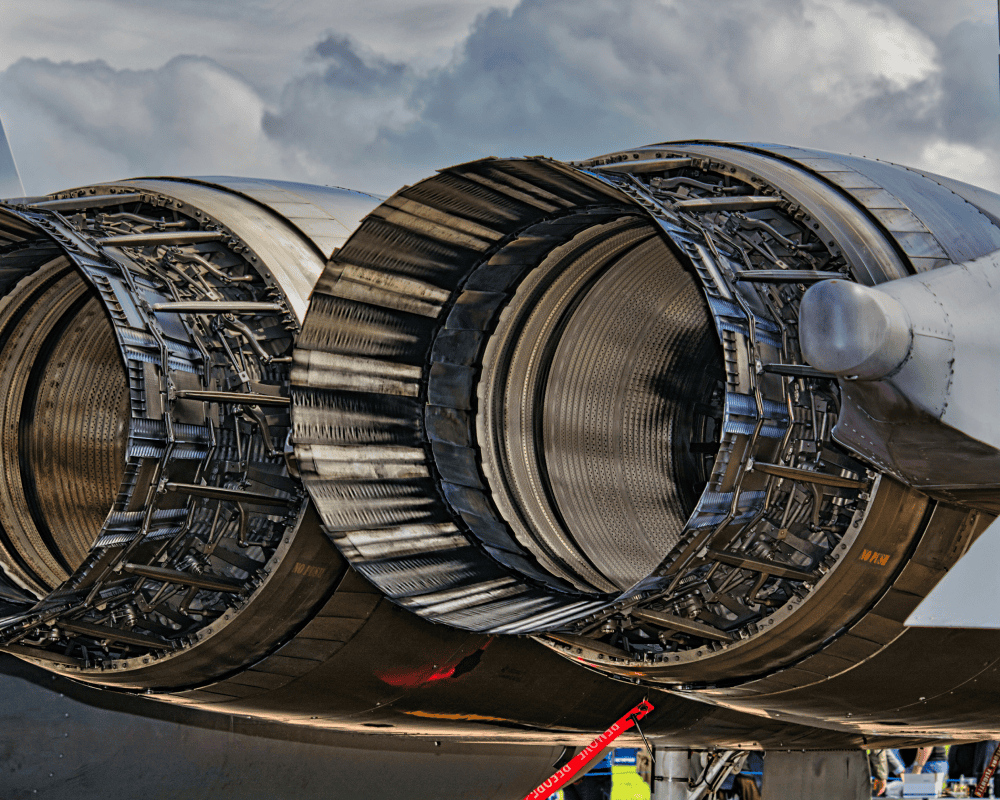

Specializing in custom bending, tube forming, welding and machining.

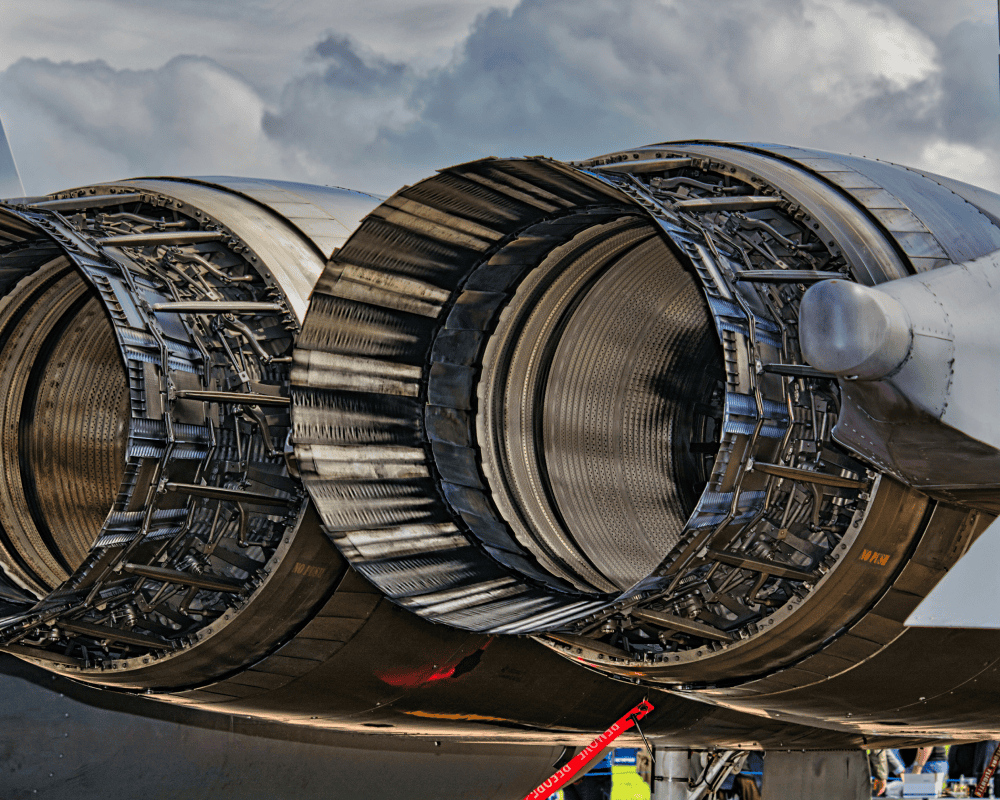

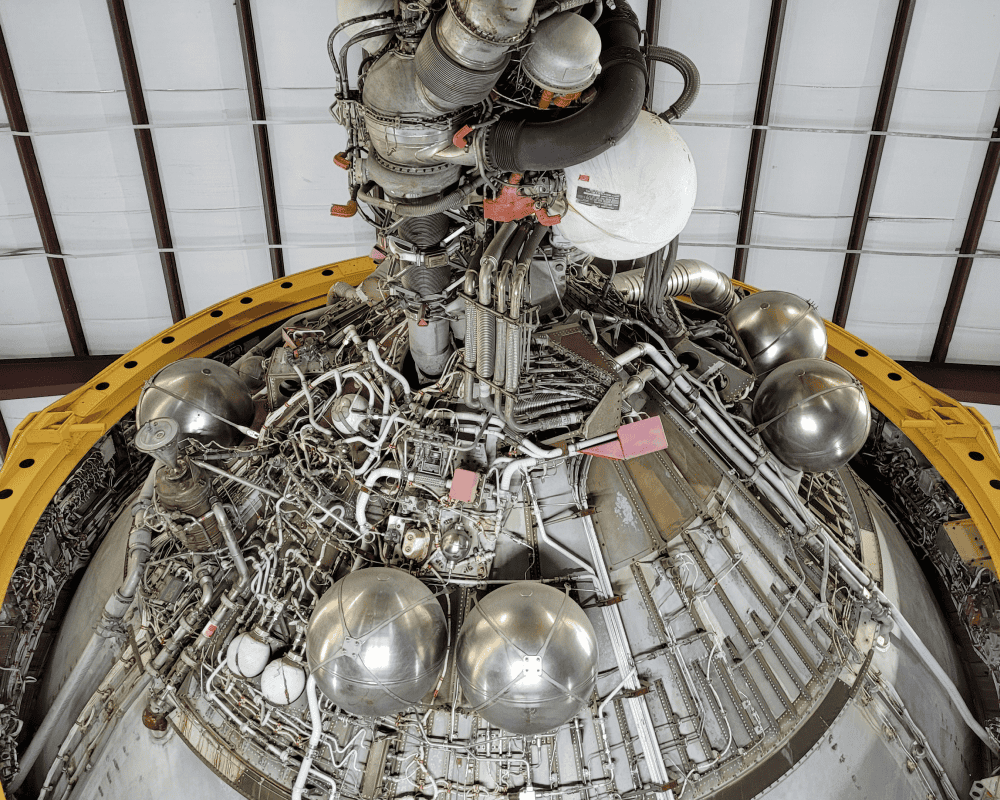

Inventors of orbital tube welding, Creative Pathways is an industry leader in orbital welding and tig welding. We build custom fabricated tubing and duct assemblies. X-ray and fluorescent penetrant. machining.

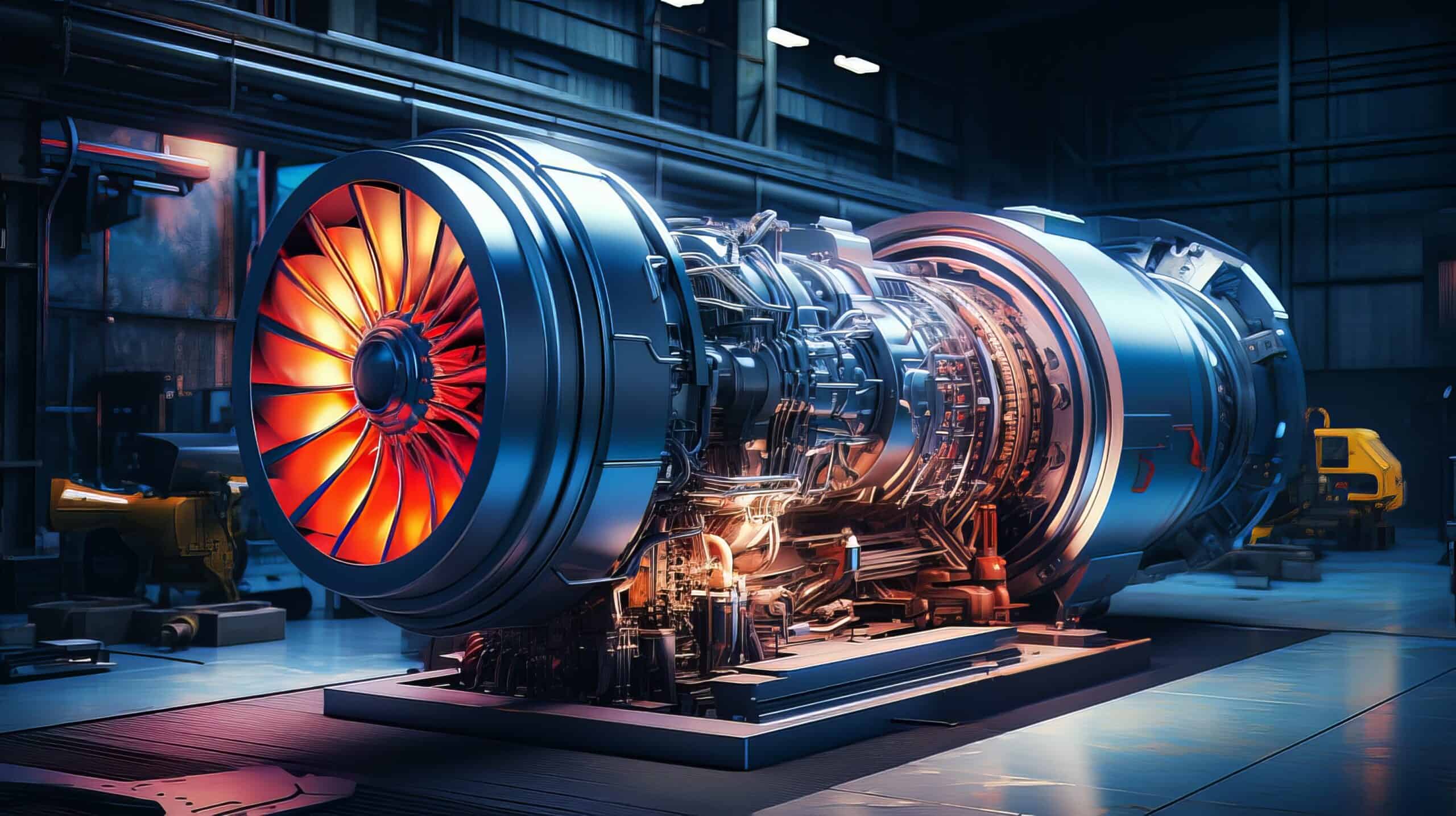

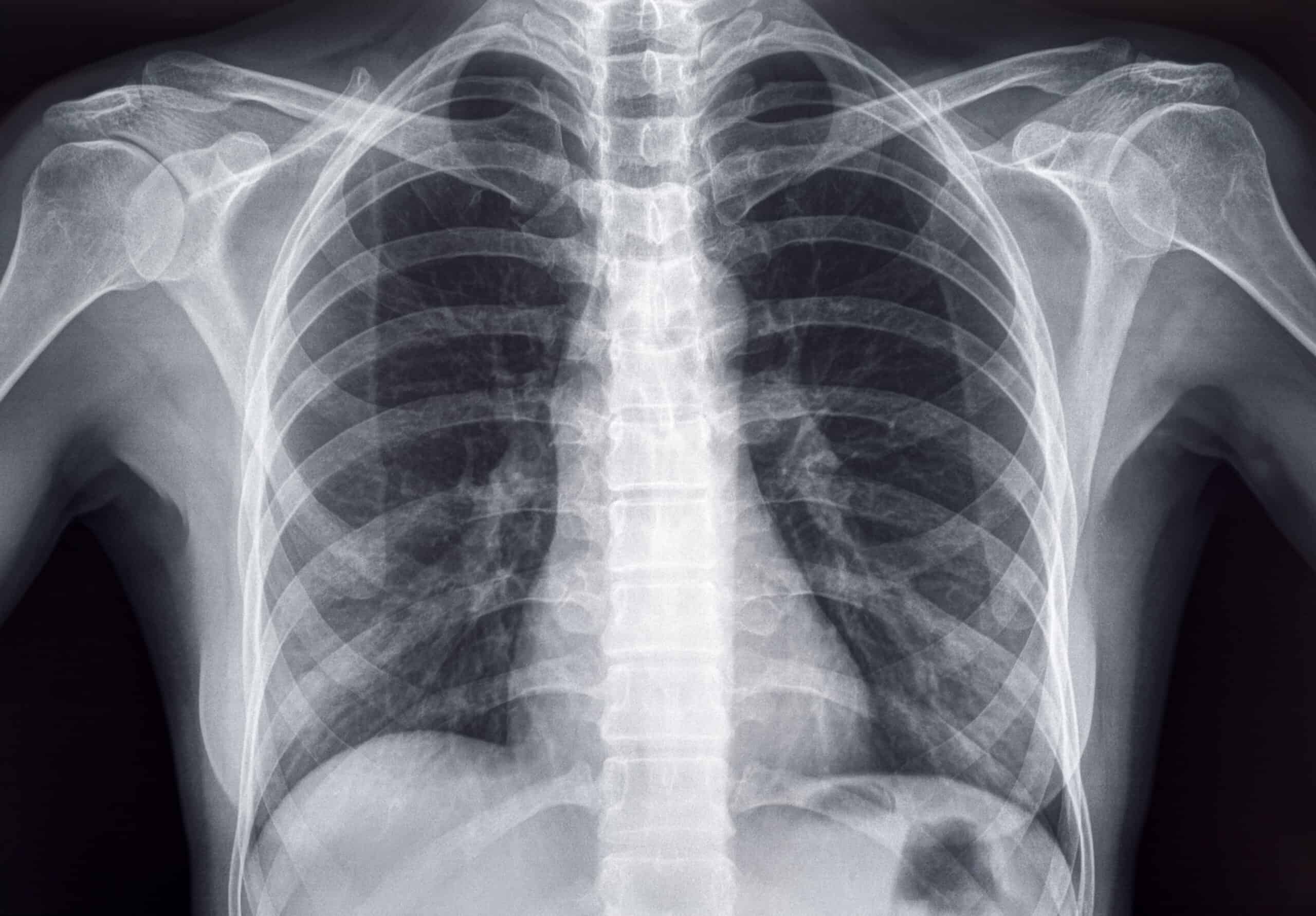

Vacuum HT and braze assemblies in the aero and medical sectors.

Vacuum Heat treat and braze assemblies coupled with aluminum dip braze and chemical processing. Silicide coatings.

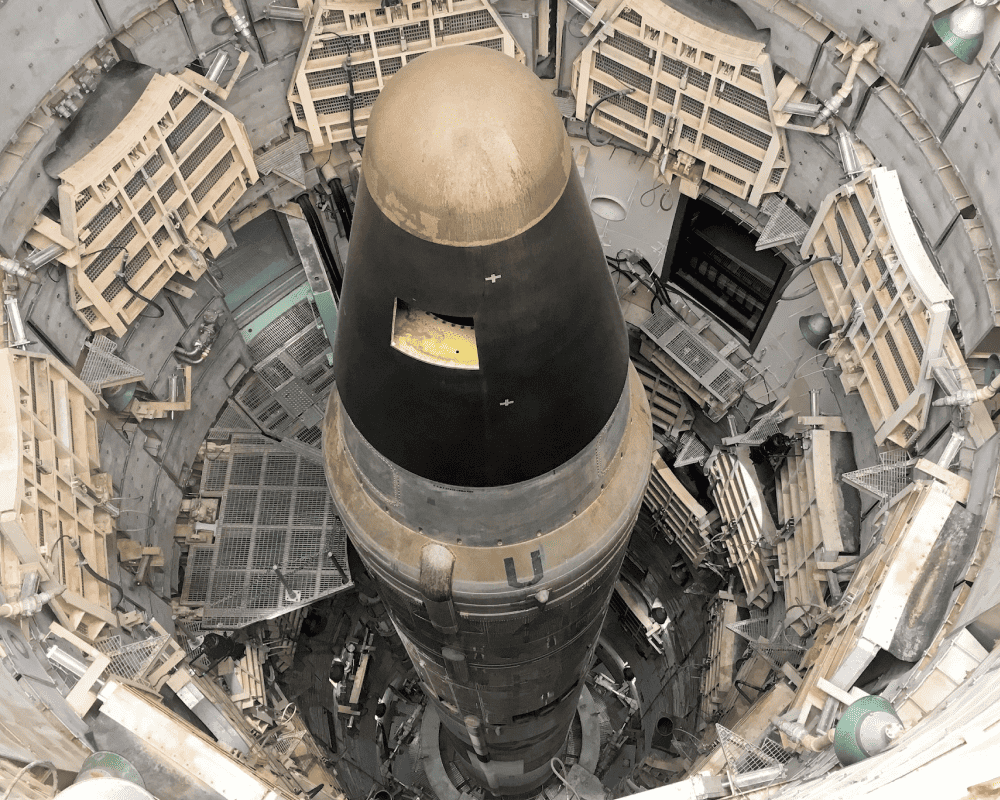

At Thermal Tube Innovations, the key to our success comes from the partnership we have with our customers and understanding where our capabilities and acquisition strategy can fill unique voids within the aerospace and defense sector.

Our strategy is to be a market leader of strategic significance as a top independent provider of tube and duct assemblies to the Aero and Defense market. Our parts solve critical with our customers on life saving hardware

We are committed to putting our customers first. We understand that building quality parts and shipping them on-time simply gets us a seat at the table. With our vertical integration, we stand out from our competitors offering shorter lead times.

NADCAP-certified orbital and TIG welding services ensuring precise, high-quality welds that meet aerospace and defense industry standards.

NADCAP-certified non-destructive testing (NDT) services that ensure material integrity and compliance without compromising part performance.

NADCAP-certified vacuum heat treating services that deliver consistent, high-strength results with superior cleanliness and control.

Precision heat treatment and vacuum brazing services engineered for strength, cleanliness, and exacting thermal performance.

High-performance silicide coating services that enhance oxidation resistance and extend the life of critical metal components.

Durable nickel plating services that provide corrosion resistance, uniform coverage, and enhanced surface performance.

Precision dip brazing solutions ideal for joining complex aluminum assemblies with strength and thermal conductivity.

Certified Class 100 clean room environment for contamination-sensitive processes and critical component handling.

High-precision CNC machining and EDM drilling for tight-tolerance parts with complex geometries and fine details.

Complete turnkey fabrication services from individual components to fully integrated, ready-to-install assemblies.